How is aluminum honeycomb furniture produced?

Aluminum honeycomb furniture is a modern furniture made of aluminum honeycomb sandwich panels, which has the characteristics of lightweight, functional, and environmentally friendly. The surface layer can be made of natural stone (such as marble, granite, cave stone), quartz stone, and acrylic stone, with a thickness usually only 3-6mm. This structure overturns the concept of traditional solid stone furniture and brings unparalleled advantages.

Here’s a detailed breakdown of how aluminum honeycomb furniture is produced, from design to finished product.

The Step-by-Step Production Process

Step 1: Design and Engineering

Step 2: Manufacturing Aluminum Honeycomb Panel

Core material preparation:

The aluminum foil is subjected to processes such as coating, stacking, and stretching to form a stable hexagonal honeycomb core material, which is then cut to the desired thickness.

Panel and adhesive coating:

Clean the aluminum plate and evenly apply adhesive, then laminate and heat press the panel, honeycomb core material, and backboard to form a complete, high-strength sandwich structure.

It is also available to click here to see detail information for the production.

https://www.alcomb.com/news/what-is-the-production-process-of-aluminum-honeycomb-panel

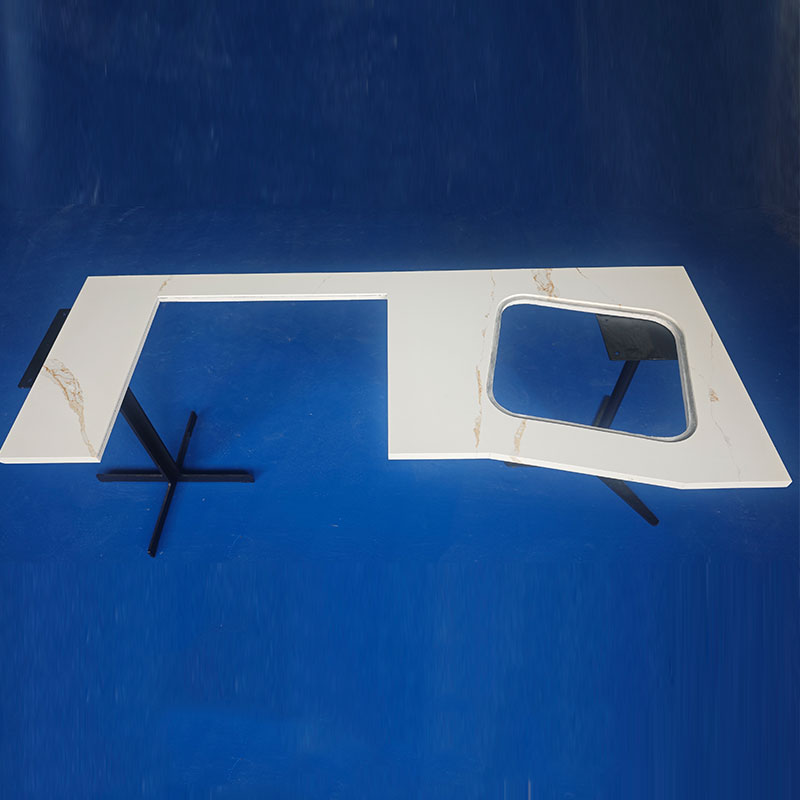

Step 3: Composited stone honeycomb panels

Select the required stone materials, including natural stones such as granite and marble, quartz, arcylic solid surface or solid wood. Then composite honeycomb panels are subjected to cracking and surface treatment. Surface treatment includes polishing and grinding to ensure flatness and decorative effect.

Step 4: Edge banding and assembly

Edge sealing or edge treatment of stone honeycomb panels, including milling grooves and chamfering, to ensure installation accuracy. Assemble stone honeycomb panels with legs, frames, drawers, or other components to create the final furniture product.

Step 5: Quality inspection

Appearance inspection: There are no pits, deformations, or oil stains, and the surface color of the stone is consistent.

Performance testing: Conduct random checks on impact resistance and adhesive strength.

Size verification: Check the length, width, thickness, dimensions, and weight to ensure compliance with standards.

Key Advantages of Honeycomb Furniture

Extremely Lightweight: Makes large pieces like conference tables or doors easy to move and handle.

Remarkably Strong and Rigid: The honeycomb structure distributes weight and stress evenly, preventing sagging.

Dimensionally Stable: Resists warping, cracking, and swelling with changes in temperature and humidity much better than solid wood.

Eco-Friendly: Uses a fraction of the solid wood or other material, and the core is often made from recycled paper.

Cost-Effective: Reduces the amount of expensive solid wood or other material needed.